Thermal Protection of Encapsulated Bacillus mucilaginosus

-

摘要:目的 针对胶质芽孢杆菌(Bacillus mucilaginosus)直投式菌剂菌体存活率低及易失活等问题,对喷雾干燥复合抗热保护剂进行优化研究,以期为其菌剂生产提供理论与技术支持。方法 以直投式菌剂菌体存活率为指标,利用喷雾干燥生产工艺,考察海藻糖、脱脂奶粉、麦饭石改性材料(H-MS)对菌体的抗热保护效果;并利用响应面法对复合抗热保护剂配方进行优化。结果 不添加抗热保护剂的菌剂菌体存活率仅有(34.15±1.07)%;添加单一保护剂时,以海藻糖保护效果最佳,麦饭石改性材料(H-MS)及脱脂奶粉次之,菌体存活率分别可达(52.17±1.08)%,(51.64±0.77)%,(43.67±1.62)%,海藻糖和H-MS对菌体存活率具有极显著影响(P<0.01),脱脂奶粉对菌体存活率具有显著影响(P<0.05)。利用响应面优化得到最佳复合抗热保护剂配方为海藻糖4.33%、脱脂奶粉2.90%和麦饭石改性材料(H-MS)7.57%。在此最佳添加配比下,菌体存活率为(73.32±0.76)%,活菌数最高可达1.12×109 CFU·g−1。结论 添加3种抗热保护剂均能提高直投式菌剂菌体存活率,且三者之间存在交互作用,复合使用的抗热效果优于单独使用。扫描电镜观察显示海藻糖和脱脂奶粉将菌体包埋成微胶囊固定在麦饭石改性材料(H-MS)的孔道中,能有效保护菌体细胞,提高菌剂菌体存活率。Abstract:Objective Effect of encapsulation to protect Bacillus mucilaginosus from thermal shock was evaluated for formulation optimization.Method Rates of survival and activation of B. mucilaginosus encapsulated with trehalose, skimmed milk powder, and/or modified H-MS medical stone after spray-drying were determined. Optimal formulation for the encapsulation was obtained using the response surface method.Result The survival rate of the naked B. mucilaginosus was (34.15±1.07)%. In contrast, the encapsulation with trehalose significantly improved the rate to (52.17±1.08)% (P<0.01), while with H-MS, (51.64±0.77)% (P<0.01) and with skimmed milk powder, (43.67±1.62)% (P<0.05). Furthermore, a combined use of trehalose at 4.33%, skimmed milk powder at 2.90%, and H-MS at 7.57% for the encapsulation, the survival reached (73.32±0.76)% with a microbial count of 1.12×109 CFU·g−1.Conclusion The three encapsulation materials, especially, when they were applied in combination, significantly raised the B. mucilaginosus survival rate under a heat treatment. The scanning electron microscopic image revealed that trehalose and skimmed milk powder immobilized the bacteria cells in H-MS pores producing an effective thermal insulation that sheltered the encapsulated microbes.

-

0. 引言

【研究意义】胶质芽孢杆菌(Bacillus mucilaginosus)是一类能分解硅酸盐矿物的化能异养型好氧菌[1],广泛分布在土壤及矿石中,具有解钾、溶磷、脱硅的特性[2]。因其具有改良土壤结构、增强肥力、无毒无害等优势,被广泛应用于土壤增肥与作物防治领域[3, 4]。目前,胶质芽孢杆菌直投式菌剂的生产工艺主要为喷雾干燥和真空冷冻干燥[5]。真空冷冻干燥是利用升华原理,真空状态下使菌体细胞内外冻结的游离水升华为气体,达到干燥目的[6]。但该技术生产周期较长,技术成本高,不适合规模化生产。喷雾干燥是将物料雾化成液体微粒,再通过热空气干燥微粒而获得脱水产品的一种成熟干燥技术。该技术干燥时间短,操作条件容易控制,适合规模化生产[7]。通过喷雾干燥技术制备微生物菌剂,可使菌体与外界不良环境隔离,较好保存菌体的活性,菌剂形成近似球体的固体微颗粒[8],便于运输、储存与添加利用[9]。但喷雾干燥技术生产菌剂最大制约在于高温胁迫下菌体细胞受损与脱水死亡,因此,如何降低喷雾干燥菌体死亡率、制备高菌体存活率的直投式菌剂,对其工业化生产发展具有重要意义[10]。【前人研究进展】为了减少喷雾干燥过程中细胞损伤,通常添加具有高保护性的抗热保护剂来提高菌体存活率,抗热保护剂大体可分为有机载体与无机载体两大类。有机载体具有固化操作简易、易被微生物分解及固定化密度高等优点,主要以天然多糖类物质、蛋白类物质应用较为广泛[11],常见的有海藻糖、蔗糖、琼脂、乳清蛋白等。无机载体材料因具有机械强度高、稳定性强、传质性能优、环境友好及对细胞无毒害等特点被广泛应用[12]。常见的无机载体材料主要有沸石、蒙脱石、麦饭石、活性炭等。Soukoulis C[13]等研究发现,脱脂奶粉能增强嗜酸乳杆菌的抗热性,但菌体存活率仅能提升到59%。Alvarenga V O[14]等研究发现,单独使用滑石作为蜡状芽孢杆菌抗热保护剂,其抗热效果非常有限。Sompach G[15]等研究发现,蔗糖和分离乳清蛋白均能有效提高乳酸菌菌体存活率,而二者联用作为复合保护剂能将菌体存活率成倍提高。Agudelo[16]等研究发现,海藻糖和蔗糖双糖掺入能有效提高鼠李糖乳杆菌在乳清蛋白麦芽糊精载体中的活性,可将菌体存活率提高780倍。大量研究表明单一抗热保护剂不足以有效帮助菌体抵抗喷雾干燥过程中外界环境的恶劣变化,复配各种抗热保护剂材料,通过发挥其各自作用与联合作用能使得抗热效果大大提升,更为有效地提高菌剂的菌体存活率[17]。【本研究切入点】目前关于胶质芽孢杆菌直投式菌剂的研究报道仍较少,对其喷雾干燥的抗热应用研究更为稀缺。【拟解决的关键问题】本研究以1株胶质芽孢杆菌(Bacillus mucilaginosus)SHBCC D12018为研究对象,通过前期试验筛选确定海藻糖、脱脂奶粉、麦饭石改性材料(H-MS)作为抗热保护剂,利用喷雾干燥技术,进行直投式菌剂制备效果探究。以菌体存活率为指标,采用响应面法优化复合抗热保护剂配方[18],以期为胶质芽孢杆菌直投式菌剂的推广与应用提供有效依据。

1. 材料与方法

1.1 试验材料

1.1.1 微生物菌种及培养基

胶质芽孢杆菌(Bacillus mucilaginosus)SHBCC D12018,上海保藏生物技术中心。菌种活化及种子培养采用无氮培养基,扩大发酵培养采用含氮培养基。

无氮培养基:葡萄糖 10 g,NaCl 2 g,MgSO4·7H2O 2 g,KH2PO4 2 g,CaCO3 5 g,蒸馏水 1000 mL,pH值7.2;固体培养基加入20 g琼脂。

含氮培养基:蔗糖 10 g,酵母浸粉 1 g,NaCl 1 g,MgSO4 0.2 g,K2HPO4 0.5 g,蒸馏水 1000 mL,pH值7.2;固体培养基加入20 g琼脂。

所有培养基配制完成后经121 ℃灭菌20 min,备用。

1.1.2 主要试验材料

海藻糖(食品级),德州汇洋生物科技有限公司;脱脂奶粉(食品级),伊利集团;闽东南麦饭石,由中国冶金总局第二地质勘查院提供。

1.1.3 主要仪器与设备

SJ-CJ-1F型超净工作台,苏州净化设备有限公司;H1650-W型台式微量高速离心机,湖南湘仪实验室仪器开发有限公司;SPH-2102C型立式双层恒温培养振荡器摇床,上海世平实验设备有限公司;UV-2600A型紫外可见分光光度计,岛津实验器材有限公司;Mini UV plus型纯水机,德国赛多利斯公司;YC-015型微型喷雾干燥机,上海雅程仪器设备有限公司;LDZX-75KBS型立式高压蒸汽灭菌器,上海申安医疗器械厂;DGG-9070G型鼓风干燥箱,上海森信实验仪器有限公司。

1.2 试验方法

1.2.1 菌体发酵及喷雾干燥

将斜面保存的胶质芽孢杆菌于无氮固体培养基活化,接种至无氮液体培养基中进行种子培养,在30 ℃、150 r·min−1条件下振荡培养48 h。按体积比为5%的接种量将种子液接种于含氮液体培养基在30 ℃、150 r·min−1条件下振荡培养72 h得到发酵菌液。无菌条件下,按照试验设计方案,向菌液加入不同配比抗热保护剂后磁力搅拌20 min,使保护剂充分溶解于菌液,得到菌悬液,喷雾干燥制备菌剂。设定喷雾干燥工艺参数:进料速度8 mL·min−1,通针设定10 s,风机设定30Hz,进风温度130 ℃,出风温度80 ℃。

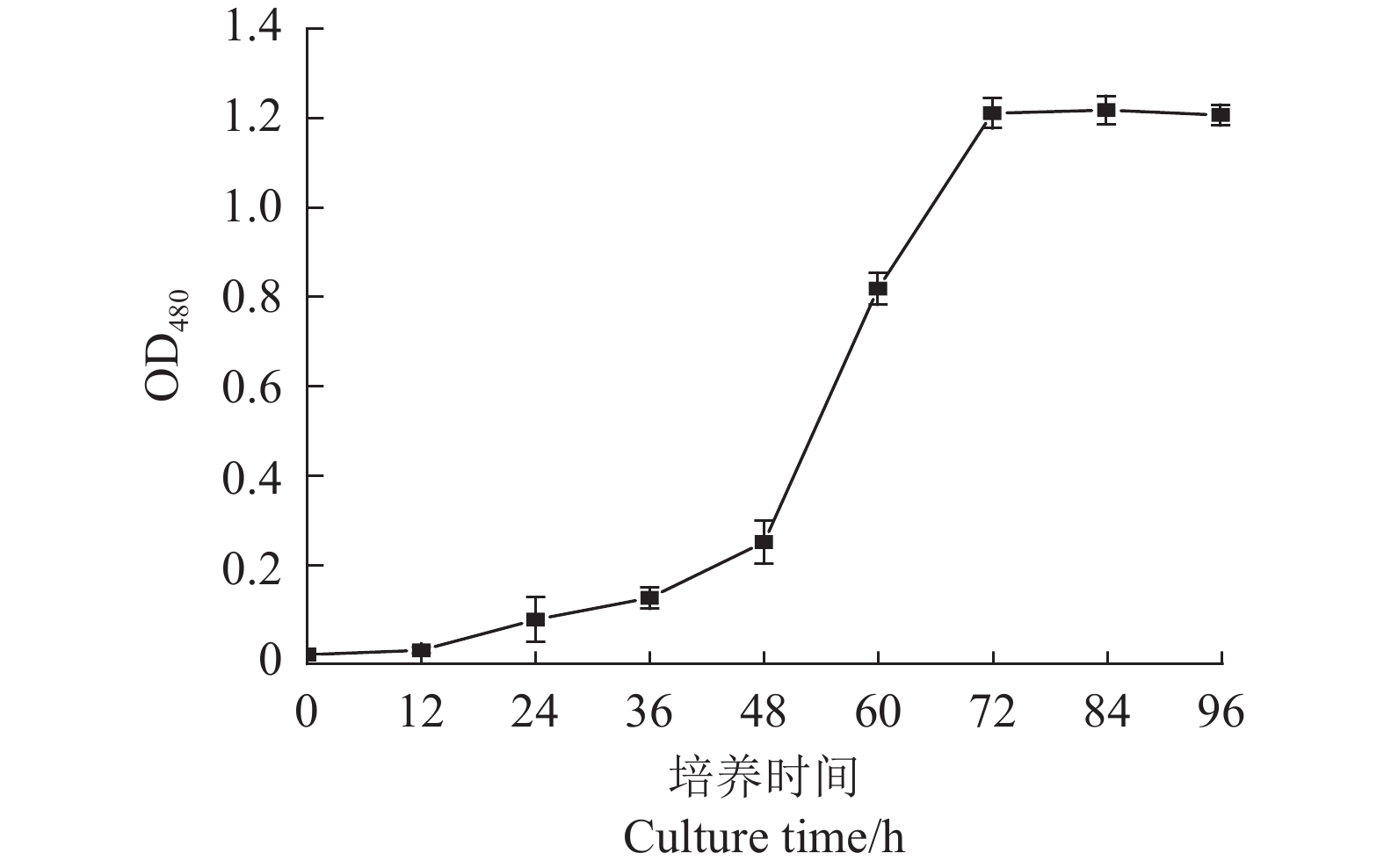

1.2.2 菌种生长特性测定

按体积比为5%接种量将种子液接种于发酵培养基,30 ℃、150 r·min−1 条件下培养。设置3个平行样,每隔6 h取样,在波长480 nm处测定其吸光值(OD值),绘制生长曲线,确定菌体最佳收获期[19]。

1.2.3 麦饭石改性材料(H-MS)制备

将麦饭石加工粉碎经400目筛网分筛,称取50 g粉体加至500 mL浓度为1 mol·L1的盐酸溶液中均匀搅拌2 h,抽滤,用超纯水冲洗至滤液成中性。再经121 ℃,高温高压灭菌20 min后,得到麦饭石改性材料(H-MS),烘干备用。

1.2.4 菌剂含水率测定

利用恒温烘干法[20]测定菌剂含水率,置于105 ℃条件下干燥至恒重,计算含水率。

含水率(%)=[干燥前质量(g)−干燥后质量(g)]/干燥前质量(g)

1.2.5 抗热保护剂单因素试验

利用不同质量分数的海藻糖(0%、2%、4%、6%、8%)、脱脂奶粉(0%、1%、2%、3%、4%)、H-MS(4%、6%、8%、10%、12%)进行单因素试验,设3次重复。

1.2.6 抗热保护剂Box-Behnken试验

结合单因素试验结果,利用Design Expert软件中Box-Behnken试验设计,设置复合抗热保护剂配方因素水平表(表1)。以菌剂菌体存活率作为响应值进行中心响应面分析,并建立二次响应面回归模型,得到拟合回归方程。利用愿望函数预测最佳工艺参数,由此确定最优响应面因子水平。而后基于最佳水平,进行3次验证性试验,与预测值比较[21]。

表 1 Box-Behnken试验设计因素水平Table 1. Factor levels in Box-Behnken experiment design水平

Level因素 Factor A 海藻糖

Trehalose/%B 脱脂奶粉 Skimmed

milk powder/%C H-MS/% −1 2 2 6 0 4 3 8 1 6 4 10 1.2.7 活菌计数与菌体存活率计算

活菌计数:平板计数法[22]。

菌液活菌数(CFU·mL−1)=平板菌群数×稀释倍数/接种量(mL)

菌剂活菌数(CFU·g−1)=平板菌群数×稀释倍数/接种量(g)

菌体存活率(%) = [菌液活菌数(CFU·mL−1)×菌液容积(mL)] / [菌剂活菌数(CFU·g−1)×菌剂质量(g)]

2. 结果与分析

2.1 胶质芽孢杆菌生长特性测定

胶质芽孢杆菌生长曲线如图1所示,0~36 h为菌株的生长迟缓期,此时期由于缺少能量和生长因子,菌体繁殖迅速缓慢;36~72 h为菌株的对数生长期,菌体数量成指数型增长;72 h后,菌体进入生长稳定期,菌体增长率和死亡率基本持平,OD值基本保持稳定;84 h时,由于营养物质缺乏,菌体的死亡率逐步超越增长率,菌体生长进入衰亡期,活菌数略有下降。根据胶质芽孢杆菌生长特性,可以确定扩大发酵培养的最佳收获期为72 h,此时菌体进入生长稳定期,菌体数量达到峰值。

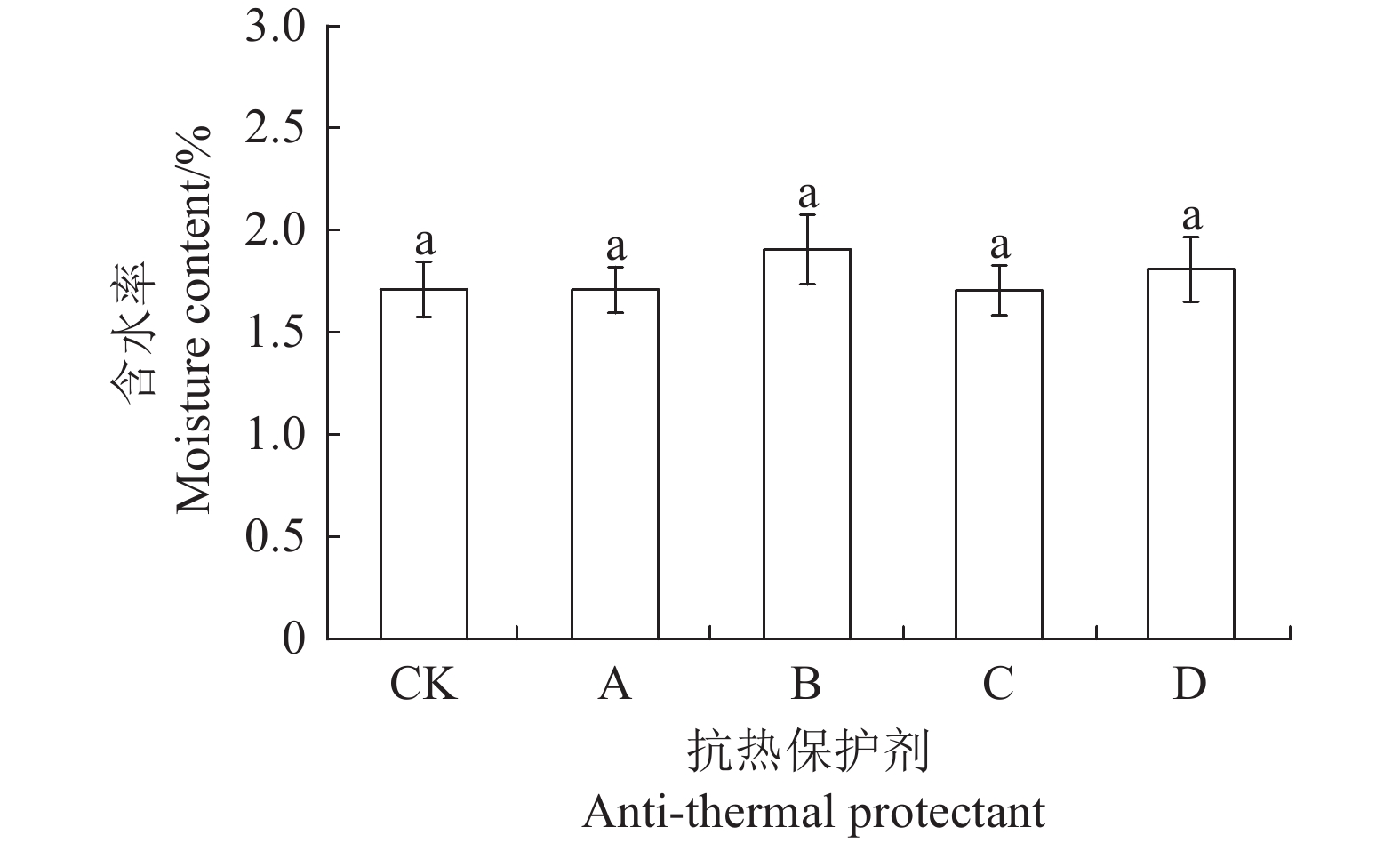

2.2 菌剂含水率

含水率是鉴定喷雾干燥菌剂质量的重要指标之一,良好的菌剂产品含水率质量分数不超过 3% [23]。 不同抗热保护剂处理下菌剂含水率测定结果如图2所示,抗热保护剂对菌剂的含水率影响均不显著(P>0.05),各组菌剂含水率均满足指标要求且保持稳定。

![]() 图 2 不同抗热保护剂处理下菌剂含水率不同小写字母表示差异显著(P<0.05);CK:空白;A:海藻糖;B:脱脂奶粉;C:H-MS;D:复合保护剂。Figure 2. Moisture content of B. mucilaginosus encapsulated with various protectantsData with different lowercase letters indicate significant differences (P<0.05); CK: blank control; A: trehalose; B: skimmed milk powder; C: H-MS; D: combination protectant.

图 2 不同抗热保护剂处理下菌剂含水率不同小写字母表示差异显著(P<0.05);CK:空白;A:海藻糖;B:脱脂奶粉;C:H-MS;D:复合保护剂。Figure 2. Moisture content of B. mucilaginosus encapsulated with various protectantsData with different lowercase letters indicate significant differences (P<0.05); CK: blank control; A: trehalose; B: skimmed milk powder; C: H-MS; D: combination protectant.2.3 单一抗热保护剂对菌体抗热性的影响

单因素试验结果如表2所示,空白组(不添加抗热保护剂)的菌体死亡率高,菌体存活率仅有(34.15±1.07)%,而添加不同比例抗热保护剂均可不同程度提高喷雾干燥热处理后菌体存活率。

表 2 单因素试验结果Table 2. Results of single factor experiment抗热保护剂

Anti-thermal

protectant添加质量分数

Appending

proportion/%菌体存活率

Bacterial survival

rate/%空白

Blank0 34.15±1.07 海藻糖

Trehalose2 41.65±2.66 c 4 52.17±1.08 a 6 50.84±1.22 ab 8 48.17±1.95 b 脱脂奶粉

Skimmed milk powder1 36.25±2.27 b 2 39.78±1.73 ab 3 43.67±1.62 a 4 41.39±2.25 a H-MS 6 47.18±1.72 c 8 51.64±0.77 a 10 50.68±0.86 ab 12 48.96±1.30 bc 同一处理组内不同小写字母表示差异显著(P<0.05)。

Different lowercase letters within the same numbered group indicate significant differences (P<0.05).其中海藻糖的保护效果最佳,菌体存活率可达(52.17±1.08)%,H-MS、脱脂奶粉次之。海藻糖、H-MS及脱脂奶粉均对菌体存活率具有显著影响(P<0.05);3因素对菌体存活率的影响排序为海藻糖>H-MS>脱脂奶粉。

随着保护剂添加比例提高,菌体存活率呈现先上升后下降的趋势。主要原因可能是由于海藻糖与脱脂奶粉添加过量,菌悬液黏度增大,干燥室腔体干燥不充分,粘壁现象严重,收集菌剂量减少;当H-MS添加过量,会造成雾化器与喷嘴堵塞,收集菌剂量骤减。且随着保护剂添加配比增大,菌剂产物重量也随着增加,单位重量产物的菌体比例变小,活菌数有所下降,加之收集菌剂量减少,导致活菌率降低。

2.4 复合抗热保护剂对菌体抗热性的影响

2.4.1 Box-Behnken试验结果

依据单因素试验结果,以海藻糖、脱脂奶粉、H-MS设置3个自变量,在3个水平上进行Box-Behnken试验设计,以喷雾干燥菌剂菌体存活率为响应值,对复合抗热保护剂配方进行优化,试验结果如表3所示。

表 3 Box-Behnken试验设计及结果Table 3. Box-Behnken experimental design and results试验号

Test numberA因素

A-factor levelB因素水平

B-factor levelC因素

C-factor level菌体存活率

Bacterial survival rate/%1 −1 −1 0 54.86 2 −1 1 0 60.14 3 1 −1 0 64.43 4 1 1 0 55.38 5 −1 0 −1 56.23 6 1 0 −1 67.53 7 −1 0 1 59.16 8 1 0 1 56.24 9 0 −1 −1 62.47 10 0 1 −1 64.61 11 0 −1 1 64.47 12 0 1 1 58.12 13 0 0 0 73.54 14 0 0 0 72.84 15 0 0 0 71.84 2.4.2 回归方程的建立

对Box-Behnken试验结果进行方差分析和响应面二次回归模型拟合,有关参数见表4。

表 4 回归模型方差分析Table 4. Analysis of variance of regression model方差来源

Variance source自由度

Freedom离差平方和

Sum of squares均方

Mean squareF值

F valueP值

P value修正模型 Model 9 570.65 63.41 64.05 0.0001 A 1 21.75 21.75 21.97 0.0054 B 1 7.96 7.96 8.04 0.0364 C 1 20.64 20.64 20.85 0.0060 AB 1 51.34 51.34 51.86 0.0008 AC 1 50.55 50.55 51.07 0.0008 BC 1 18.02 18.02 18.20 0.0080 A2 1 256.36 256.36 258.98 < 0.0001 B2 1 120.17 120.17 121.40 0.0001 C2 1 78.72 78.72 79.53 0.0003 残差 Residual 5 4.95 0.99 失拟项 Lack of fit 3 3.49 1.16 1.59 0.4080 纯误差 Pure error 2 1.46 0.73 总计 Total 14 575.60 由回归模型参数可以看出,模型显著性极高(P <0.01),海藻糖和H-MS对菌体存活率具有极显著影响( P <0.01),脱脂奶粉对菌体存活率具有显著影响( P <0.05),二次项及交互作用项均对菌体存活率有显著影响(P<0.05)。3个因素对菌体存活率影响效果排序:海藻糖>H-MS>脱脂奶粉,与单因素试验结果一致。各因素与响应值之间存在非线性关系,模型失拟项P值=0.4080>0.05为不显著,说明所拟合的二次模型信任度高,能够进行试验预测。模型决定系数R2=0.9917,表明菌体存活率约有99.17%能由各因素进行说明与决定,而调整后R2=0.9759,表明模型预测值与实际值具有较好的相关性[24]。

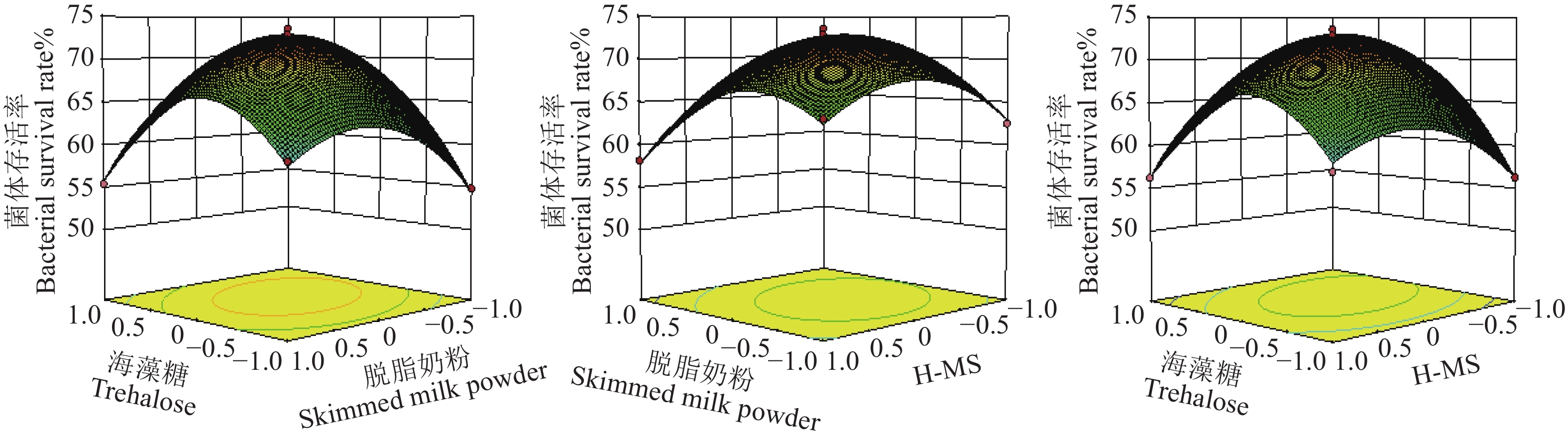

观察两因素交互作用对响应值的影响,采用降维分析(Dimension reduction analysis,DRA)即保持某因素在零水平情况下,观察另外两个因素交互作用对响应值的影响并得到其响应面及等高线[25]。由图3可知,3个因素两两交互,菌体存活率呈现先上升后下降趋势,响应面图发生弯曲,表明菌体存活率与3个因素之间为非线性关系。降维分析结论与单因素试验结果保持一致,且3因素产生的交互作用项AB、AC,BC的等高线图均为椭圆形,表明交互效应显著。

2.4.3 响应面水平优化

经二次回归模型拟合的回归方程为Y=72.74+1.65A-1.00B-1.61C-3.58AB-3.56AC-2.12BC-8.33A2-5.70B2-4.62C2

利用Design Expert软件中的Numerical优化模块(愿望函数优化),将愿望值目标设定为菌体存活率最大值。通过愿望函数优化解,得到一组最佳值:A(海藻糖)=4.33%,B(脱脂奶粉)=2.90%,C(H-MS)=7.57%,在此最佳条件下给出的菌体存活率预测值为73.10%。此时愿望函数值为0.98,表明预测值具有较好的可靠性。在此最优条件下进行3次验证试验,活菌数最高可达1.12×109 CFU·g−1,菌体存活率为(73.32±0.76)%,与模型预测值73.10%接近。

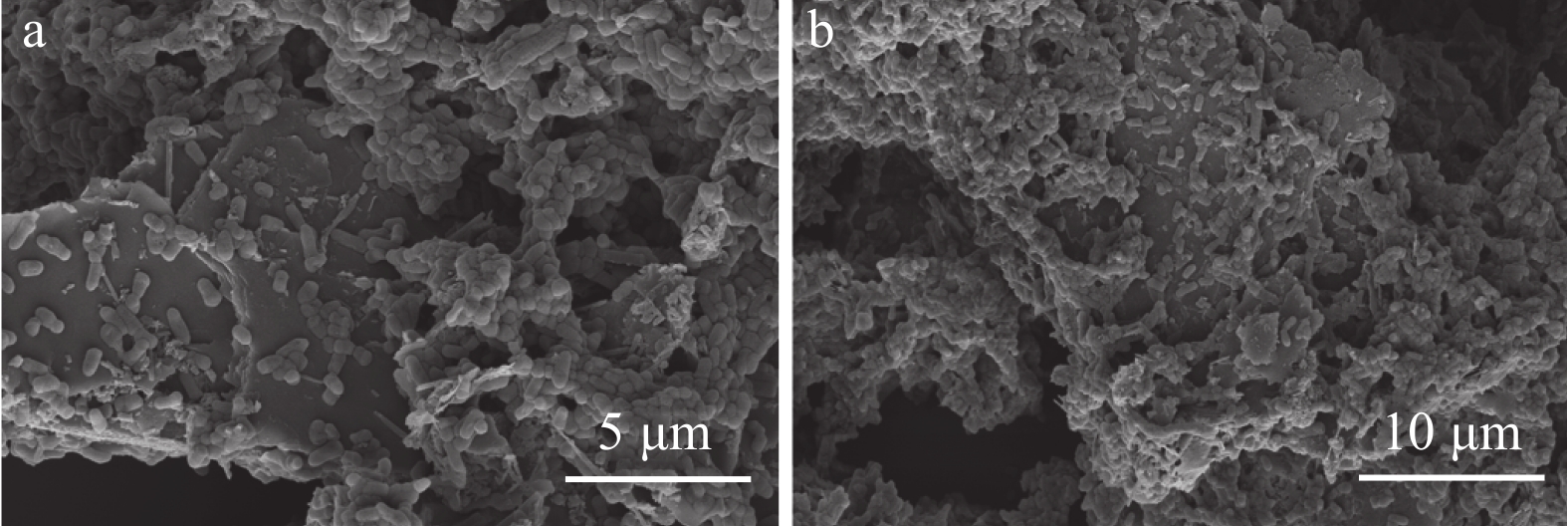

2.5 菌剂微观形态观察

菌剂微观形貌如图4所示,H-MS材料上存在大量杆状的胶质芽孢杆菌以及椭圆至圆形的芽孢被海藻糖与脱脂奶粉包覆所形成的微胶囊颗粒结构,颗粒外观平滑完整,保持良好的形貌特征。这是由于脱脂奶粉覆盖细胞形成疏水保护层,海藻糖转化为高黏度的无定形态加强了保护层的致密性,更为有效保护胶囊中菌体组织。而H-MS作为固定化材料,其无定形溶蚀孔道结构为菌体提供了良好的附着点位与适合的微环境体系来抵御外界损害。被海藻糖和脱脂奶粉所包裹的菌体颗粒附着充斥在H-MS的孔道及裂缝腔体中,且H-MS的多孔结构没有没破坏,能保证固定化菌剂在后续使用过程中发挥其效能。

3. 讨论与结论

研究发现,单独添加海藻糖、脱脂奶粉、H-MS等3种抗热保护剂均能一定程度提高菌体的抗热性,降低喷雾干燥过程中的菌体死亡率。三者保护机理为:海藻糖能在菌体生物组织经历高温脱水时替代水分子,维持细胞膜的结构与流动性,提高细胞组织的稳定性,且海藻糖在干燥状态下具有较高的玻璃态转化温度,在高温状态下会形成无定形态的高黏度干颗粒[26],紧密包埋菌体形成物理屏障,以胞外作用减少菌体的损伤,限制有害化学反应的发生;脱脂奶粉中天然乳清蛋白分子中疏水基团与菌体表面存在疏水作用,通过紧密覆盖在菌体细胞表面形成保护层,能有效降低高温环境下细胞的水损失[27];麦饭石是一种天然硅酸盐矿物,属于火成岩类中的石英斑岩,具有一定的生物活性、吸附性能以及pH调节能力,无毒无害,在喷雾干燥脱水环境下,能有效将游离微生物吸附固定在载体材料上,在保持生物活性的条件下使其高度密集[28],有效提高生物对环境胁迫的抗性。

利用Box-Behnken试验设计响应面法对复合抗热保护剂配方进行优化,结果表明抗热保护剂之间存在交互作用。海藻糖和脱脂奶粉将菌体包埋形成的微胶囊被有效固定在H-MS材料的平台空洞和溶蚀裂隙中,使菌体在受到的外界损害降低。优化得到最佳复合抗热保护剂组分,即海藻糖添加量 4.33%、脱脂奶粉添加量2.90% 和H-MS添加量7.57%。在此最优条件下,菌体存活率为(73.32±0.76)%,菌粉的活菌数最高可达1.12×109 CFU·g−1。

-

图 2 不同抗热保护剂处理下菌剂含水率

不同小写字母表示差异显著(P<0.05);CK:空白;A:海藻糖;B:脱脂奶粉;C:H-MS;D:复合保护剂。

Figure 2. Moisture content of B. mucilaginosus encapsulated with various protectants

Data with different lowercase letters indicate significant differences (P<0.05); CK: blank control; A: trehalose; B: skimmed milk powder; C: H-MS; D: combination protectant.

表 1 Box-Behnken试验设计因素水平

Table 1 Factor levels in Box-Behnken experiment design

水平

Level因素 Factor A 海藻糖

Trehalose/%B 脱脂奶粉 Skimmed

milk powder/%C H-MS/% −1 2 2 6 0 4 3 8 1 6 4 10 表 2 单因素试验结果

Table 2 Results of single factor experiment

抗热保护剂

Anti-thermal

protectant添加质量分数

Appending

proportion/%菌体存活率

Bacterial survival

rate/%空白

Blank0 34.15±1.07 海藻糖

Trehalose2 41.65±2.66 c 4 52.17±1.08 a 6 50.84±1.22 ab 8 48.17±1.95 b 脱脂奶粉

Skimmed milk powder1 36.25±2.27 b 2 39.78±1.73 ab 3 43.67±1.62 a 4 41.39±2.25 a H-MS 6 47.18±1.72 c 8 51.64±0.77 a 10 50.68±0.86 ab 12 48.96±1.30 bc 同一处理组内不同小写字母表示差异显著(P<0.05)。

Different lowercase letters within the same numbered group indicate significant differences (P<0.05).表 3 Box-Behnken试验设计及结果

Table 3 Box-Behnken experimental design and results

试验号

Test numberA因素

A-factor levelB因素水平

B-factor levelC因素

C-factor level菌体存活率

Bacterial survival rate/%1 −1 −1 0 54.86 2 −1 1 0 60.14 3 1 −1 0 64.43 4 1 1 0 55.38 5 −1 0 −1 56.23 6 1 0 −1 67.53 7 −1 0 1 59.16 8 1 0 1 56.24 9 0 −1 −1 62.47 10 0 1 −1 64.61 11 0 −1 1 64.47 12 0 1 1 58.12 13 0 0 0 73.54 14 0 0 0 72.84 15 0 0 0 71.84 表 4 回归模型方差分析

Table 4 Analysis of variance of regression model

方差来源

Variance source自由度

Freedom离差平方和

Sum of squares均方

Mean squareF值

F valueP值

P value修正模型 Model 9 570.65 63.41 64.05 0.0001 A 1 21.75 21.75 21.97 0.0054 B 1 7.96 7.96 8.04 0.0364 C 1 20.64 20.64 20.85 0.0060 AB 1 51.34 51.34 51.86 0.0008 AC 1 50.55 50.55 51.07 0.0008 BC 1 18.02 18.02 18.20 0.0080 A2 1 256.36 256.36 258.98 < 0.0001 B2 1 120.17 120.17 121.40 0.0001 C2 1 78.72 78.72 79.53 0.0003 残差 Residual 5 4.95 0.99 失拟项 Lack of fit 3 3.49 1.16 1.59 0.4080 纯误差 Pure error 2 1.46 0.73 总计 Total 14 575.60 -

[1] 田稼, 吴小杰, 孙超, 等. 胶质芽孢杆菌(Bacillus mucilaginosus)的研究进展 [J]. 中国土壤与肥料, 2017(6):15−22. DOI: 10.11838/sfsc.20170603 TIAN J, WU X J, SUN C, et al. Research progress on Bacillus mucilaginosus [J]. Soil and Fertilizer Sciences in China, 2017(6): 15−22.(in Chinese) DOI: 10.11838/sfsc.20170603

[2] MUSAH B I, PENG L, XU Y F. Biosorption of Cr (VI) using Bacillus licheniformis and Bacillus mucilaginosus Krassilnikov: Contrastive investigation on removal performance, kinetics, and mechanisms [J]. Environmental Engineering Science, 2021, 38(4): 231−244. DOI: 10.1089/ees.2020.0190

[3] 杨榕, 李博文, 刘微. 胶质芽孢杆菌对印度芥菜富集土壤Cd及土壤pH的影响 [J]. 环境科学学报, 2013, 33(6):1648−1654. YANG R, LI B W, LIU W. Effects of Bacillus mucilaginosus on soil pH and Cd accumulation by Brassica juncea [J]. Acta Scientiae Circumstantiae, 2013, 33(6): 1648−1654.(in Chinese)

[4] BASAK B B, MAITY A, RAY P, et al. Potassium supply in agriculture through biological potassium fertilizer: A promising and sustainable option for developing countries [J]. Archives of Agronomy and Soil Science, 2022, 68(1): 101−114. DOI: 10.1080/03650340.2020.1821191

[5] 李宝磊. 真空冷冻干燥对乳酸菌损伤机制及关键保护技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2011. LI B L. Freeze-drying damage mechanism of lactic acid bacteria and the key protection technology research[D]. Harbin: Harbin Institute of Technology, 2011. (in Chinese)

[6] 贺金梅, 刘俊轩, 孙颖, 等. 固态微生物菌剂干燥和菌体保存的研究进展 [J]. 食品工业科技, 2012, 33(15):423−427. HE J M, LIU J X, SUN Y, et al. Research progress in drying of solid microbial agent and protection of cell [J]. Science and Technology of Food Industry, 2012, 33(15): 423−427.(in Chinese)

[7] 关鹏翔. 哈密瓜果粉喷雾干燥工艺及品质研究[D]. 杭州: 浙江工商大学, 2013. GUAN P X. Studies on the spray drying technology of cantaloup juice powder and relative quality research[D]. Hangzhou: Zhejiang Gongshang University, 2013. (in Chinese)

[8] WANG N, FU N, CHEN X D. The extent and mechanism of the effect of protectant material in the production of active lactic acid bacteria powder using spray drying: A review [J]. Current Opinion in Food Science, 2022, 44: 100807. DOI: 10.1016/j.cofs.2022.01.003

[9] KAWAKITA R, LEVEAU J H J, JEOH T. Optimizing viability and yield and improving stability of Gram-negative, non-spore forming plant-beneficial bacteria encapsulated by spray-drying [J]. Bioprocess and Biosystems Engineering, 2021, 44(11): 2289−2301. DOI: 10.1007/s00449-021-02604-9

[10] 赵彦巧, 王月, 孟翔宇, 等. 喷雾干燥法制备玫瑰茄花色苷微胶囊条件优化 [J]. 福建农业学报, 2021, 36(1):104−114. ZHAO Y Q, WANG Y, MENG X Y, et al. Optimized preparation of spray-dried anthocyanins microcapsules [J]. Fujian Journal of Agricultural Sciences, 2021, 36(1): 104−114.(in Chinese)

[11] KHEM S, SMALL D M, MAY B K. The behaviour of whey protein isolate in protecting Lactobacillus plantarum [J]. Food Chemistry, 2016, 190: 717−723. DOI: 10.1016/j.foodchem.2015.06.020

[12] 张武, 董春霞, 纪妍妍. 石油降解菌的固定化材料研究进展 [J]. 材料导报, 2017, 31(S2):214−218. ZHANG W, DONG C X, JI Y Y. Progress of research on carrier materials for oil degrading bacteria immobilization [J]. Materials Review, 2017, 31(S2): 214−218.(in Chinese)

[13] SOUKOULIS C, BEHBOUDI-JOBBEHDAR S, YONEKURA L, et al. Impact of milk protein type on the viability and storage stability of microencapsulated Lactobacillus acidophilus NCIMB 701748 using spray drying [J]. Food and Bioprocess Technology, 2014, 7(5): 1255−1268. DOI: 10.1007/s11947-013-1120-x

[14] ALVARENGA V O, CAMPAGNOLLO F B, PIA A K R, et al. Quantifying the responses of three Bacillus cereus strains in isothermal conditions and during spray drying of different carrier agents [J]. Frontiers in Microbiology, 2018, 9: 1113. DOI: 10.3389/fmicb.2018.01113

[15] SOMPACH G, RODKLONGTAN A, NITISINPRASERT S, et al. Microencapsulating role of whey protein isolate and sucrose in protecting the cell membrane and enhancing survival of probiotic lactobacilli strains during spray drying, storage, and simulated gastrointestinal passage [J]. Food Research International, 2022, 159: 111651. DOI: 10.1016/j.foodres.2022.111651

[16] AGUDELO J, CANO A, GONZÁLEZ-MARTÍNEZ C, et al. Disaccharide incorporation to improve survival during storage of spray dried Lactobacillus rhamnosus in whey protein-maltodextrin carriers [J]. Journal of Functional Foods, 2017, 37: 416−423. DOI: 10.1016/j.jff.2017.08.014

[17] 张雯, 王芳婷, 庞锦程, 等. 枯草芽孢杆菌BS08复合抗热保护剂的工艺配方优化 [J]. 食品与发酵工业, 2022, 48(17):35−41. DOI: 10.13995/j.cnki.11-1802/ts.029713 ZHANG W, WANG F T, PANG J C, et al. Formulation optimization of compound anti-thermal protectant of Bacillus subtilis BS08 [J]. Food and Fermentation Industries, 2022, 48(17): 35−41.(in Chinese) DOI: 10.13995/j.cnki.11-1802/ts.029713

[18] 孙丛, 付瑶, 王娅丽, 等. 喷雾干燥法制备阿特拉津降解菌剂条件优化 [J]. 中国农学通报, 2018, 34(35):86−92. DOI: 10.11924/j.issn.1000-6850.casb18060002 SUN C, FU Y, WANG Y L, et al. Optimization of atrazine degradation bacteria by spray drying [J]. Chinese Agricultural Science Bulletin, 2018, 34(35): 86−92.(in Chinese) DOI: 10.11924/j.issn.1000-6850.casb18060002

[19] 赵月, 杨亚楠, 李雅华, 等. 生防细菌蜡样芽孢杆菌BCCY-22发酵条件优化 [J]. 福建农业学报, 2022, 37(7):938−945. ZHAO Y, YANG Y N, LI Y H, et al. Optimizing fermentation of biocontrol bacterium Bacillus cereus BCCY-22 [J]. Fujian Journal of Agricultural Sciences, 2022, 37(7): 938−945.(in Chinese)

[20] SIDDIQUI Z S, ALI F, UDDIN Z. Sustainable effect of a symbiotic nitrogen-fixing bacterium Sinorhizobium meliloti on nodulation and photosynthetic traits of four leguminous plants under low moisture stress environment [J]. Letters in Applied Microbiology, 2021, 72(6): 714−724. DOI: 10.1111/lam.13463

[21] 林金新, 蔡少丽, 王芳婷, 等. 白酒丢糟的多菌种混菌固态发酵制备有机肥 [J]. 福建师范大学学报(自然科学版), 2017, 33(3):69−77. LIN J X, CAI S L, WANG F T, et al. Optimization on process condition in solid-state fermentation of vinasse for organic fertilizer [J]. Journal of Fujian Normal University (Natural Science Edition), 2017, 33(3): 69−77.(in Chinese)

[22] GORSUCH J P, JONES Z, SAINT D L, et al. Enumeration of industrial Bacillus assemblages in commercial products with customized plate-counting assays [J]. Journal of Microbiological Methods, 2019, 164: 105682. DOI: 10.1016/j.mimet.2019.105682

[23] 陆璐. 微生态制剂工大2号包埋与喷雾干燥工艺研究[D]. 大连: 大连工业大学, 2018 LU L. Study on embedding and spray drying process of probiotic gongda Ⅱ[D]. Dalian: Dalian Polytechnic University, 2018. (in Chinese)

[24] 肖怀秋, 李玉珍, 林亲录, 等. 枯草芽孢杆菌Prob1822复合抗热保护剂的研究 [J]. 中国酿造, 2019, 38(10):49−54. DOI: 10.11882/j.issn.0254-5071.2019.10.011 XIAO H Q, LI Y Z, LIN Q L, et al. Compound anti-thermal protectant of Bacillus subtilis Prob1822 [J]. China Brewing, 2019, 38(10): 49−54.(in Chinese) DOI: 10.11882/j.issn.0254-5071.2019.10.011

[25] KHATIB I, CHOW M Y T, RUAN J F, et al. Modeling of a spray drying method to produce ciprofloxacin nanocrystals inside the liposomes utilizing a response surface methodology: Box-Behnken experimental design [J]. International Journal of Pharmaceutics, 2021, 597: 120277. DOI: 10.1016/j.ijpharm.2021.120277

[26] 傅楠, 陈晓东. 益生菌在喷雾干燥过程中的活性变化与保护策略 [J]. 化工进展, 2018, 37(5):1633−1645. FU N, CHEN X D. Changes in the viability of probiotics during spray drying process and the strategies to protect probiotic cells [J]. Chemical Industry and Engineering Progress, 2018, 37(5): 1633−1645.(in Chinese)

[27] ARSLAN S, ERBAS M, TONTUL I, et al. Microencapsulation of probiotic Saccharomyces cerevisiae var. boulardii with different wall materials by spray drying [J]. LWT - Food Science and Technology, 2015, 63(1): 685−690. DOI: 10.1016/j.lwt.2015.03.034

[28] 周庆, 陈杏娟, 许玫英. 微生物菌剂在难降解有机污染治理的研究进展 [J]. 微生物学通报, 2013, 40(4):669−676. ZHOU Q, CHEN X J, XU M Y. Recent research progress in microbial agents for treatment of refractory organic contaminants [J]. Microbiology China, 2013, 40(4): 669−676.(in Chinese)

-

期刊类型引用(1)

1. 安呈洁,张武. 不同比例芽孢杆菌对常见温室蔬菜病原菌抑制研究. 现代农业研究. 2024(07): 94-97 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: